COMPARISON CHART OF BURNER

| Parameters | Navshakti | Other Brand |

|---|---|---|

| Material (Firing Chamber) | SS 310/10mm | SS 304 / Refractory |

| Material (Outer Chamber) | SS 304 | SS 304 / MS |

| Outer Nozzle | SS 304 | SS 304 / MS |

| Inner Nozzle | SS 310/10mm | SS 304 / MS |

| Ignition System | Automatic | Manually |

| Screw Pipe & Other Assessories | SS-304 | MS |

| Control System | Automatic/PID | Only PID |

| Efficiency | 85% | 70% |

| Cleaning of Ash/Clanker | Clean Easily Due to SS Chamber | Clinker stick with refractory, causing damage of refractory. |

| Maintances | Maintaces Free | Refractory & Nozzle maintances Every 3-6 month. |

| Service Support | 24/7 & Locally | No Service Support |

| Pellet feeding system | Timer/VFD | Timer Based |

| Blower Motor | CG/Standard | Standard |

| Geared Motor | Made in Taiwan | Standard |

| Flame Controller | Available | Not Available |

| Air Flow Control | Automatic | Manually |

| Designing | Compact | Bulky |

| Burner Life | More than 4 years | Less than 2 years |

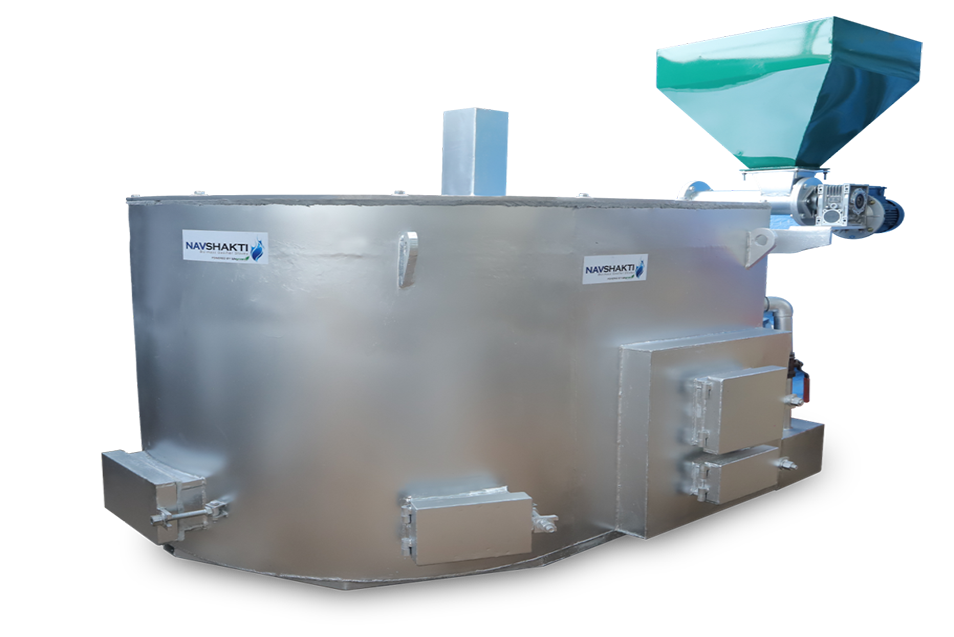

COMPARISON CHART OF TURBO

| Inner Chamber | Navshakti | Other Brand |

|---|---|---|

| Inner Chamber | SS 310 (10mm Thickness) | SS 304/ SS (6mm Thickness) |

| Outer Chamber | SS 304 (3mm Thickness) | SS 202/ MS |

| Screw Pipe | SS 304 | MS |

| Ignition | Automatic | Manual |

| Hopper Capacity | Upto 35 kgs | Upto 20 kgs |

| Geared Motor | Made in Taiwan | Local Manufacture |

| Feeding Screw | MS 5mm Thickness | Spring Type |

| Designing | Compact Due to SS | Bulky Due to Refractory & MS |

| Ease of Operation | Highly Easy to Operate | Difficult to Operate |

| Insulation | Three Layer | Two Layer |

| Flame Monitoring Glass | Available | Not Available |

| Blower | High CFM & Pressure | Low CFM & Pressure |

| Feeding Rates of Pellet | Can be set in Fractions | Can be Only set in Secondary |

| Burner Installation | Within 4 Hours | Time Consuming |

| Hopper | Covered | Open |

| Cleaning | Very Easy | Very Tough |

COMPARISON CHART FOR ALUMINIUM MELTING FURNACES

| Parameters | Navshakti | Other Brand | Remarks |

|---|---|---|---|

| Efficiency | 80% | 60% | Navshakti furnaces consumes less fuel and increase productivity |

| Pellet feeding system | VFD | Timer Based | Due to continuition in flow of pellets air to fuel ratio will be proper hence no chance of smoke |

| Insulation type | Three Layer bricks insulation of 70% Allumina | Two Layer bricks insulation of 70% Allumina | Navshakti furnaces has three layer insulation with high quality allumina results in less heat wastage |

| Blower Motor | CG/ABB/Bharat | Standard | Higher motor life less maintenance |

| Geared Motor | CG/ABB/Bharat | Standard | Higher motor life less maintenance |

| Burner frame structure | MS 5mm | MS 3mm | Rugged body with high strength |

| Castable | K Type | J Type | K type castable is more heat stable then J type hence enhance refractory life and less maintenance |

| Cleaning | Easy | Tough | ...... |

| Top plate | MS 12-15 mm | MS 8-10mm | ...... |

| Flame Controller | Available | Not Available | ...... |

| Hopper Capacity | upto 100Kgs | Less then 90kgs | ...... |

| Air Flow Cotrol | Mechanically | No Control | ...... |

| Designing | Compact | Bulky | ...... |

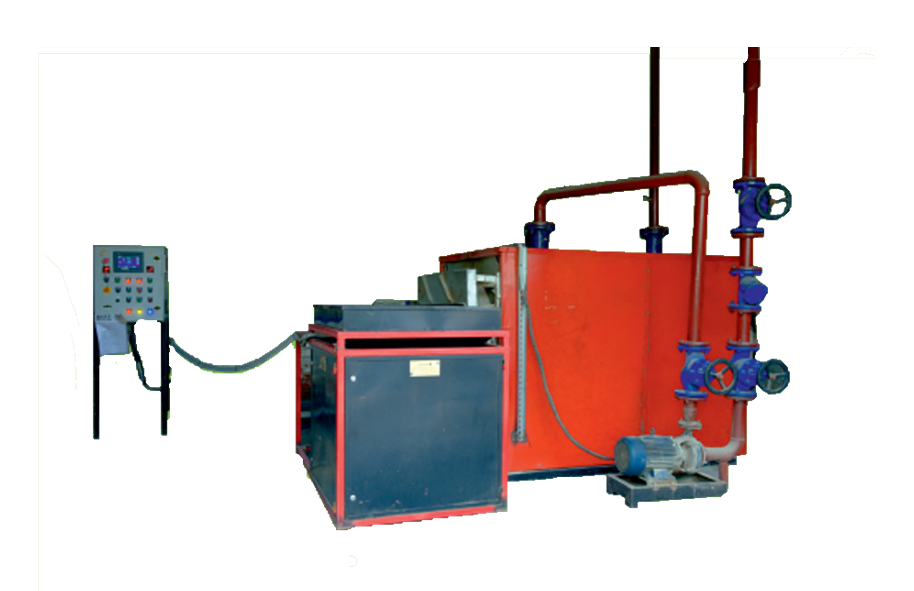

NAVSHAKTI MULTIFUEL HOT WATER GENERATOR PRODUCT DESCRIPTION

| Description | Unit | NHWG 100K | NHWG 200K | NHWG 300K | NHWG 400K | NHWG 500K | NHWG 600K |

|---|---|---|---|---|---|---|---|

| Capacity | Kcal/hr | 100000 | 200000 | 300000 | 400000 | 500000 | 600000 |

| Maximum Outlet Temperature | °C | 90 | 90 | 90 | 90 | 90 | 90 |

| Maximum Working Pressure | Bar | 5 | 5 | 5 | 5 | 5 | 5 |

| Water Flow Rate | m3/hr | 9 | 12 | 18 | 20 | 25 | 30 |

| Temperature Difference (At) | oC | 11 | 17 | 17 | 20 | 20 | 20 |

| Efficiency | |||||||

| Pellet(Burner) | % | 85.5 | 85.5 | 85.5 | 85.5 | 85.5 | 85.5 |

| Diesel (HSD) Gas (PNG / LPG) | % | 85.5 | 85.5 | 85.5 | 85.5 | 85.5 | 85.5 |

| Orientation | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal | Horizontal |

| Type of Fuel | Biomass Pellet/HSD/LPG/NG | Biomass Pellet/HSD/LPG/NG | Biomass Pellet/HSD/LPG/NG | Biomass Pellet/HSD/LPG/NG | Biomass Pellet/HSD/LPG/NG | Biomass Pellet/HSD/LPG/NG | Biomass Pellet/HSD/LPG/NG |

| Fuel Firing System | Pellet Burner, Pressure Jet, Mono-Bloc | Pellet Burner, Pressure Jet, Mono-Bloc | Pellet Burner, Pressure Jet, Mono-Bloc | Pellet Burner, Pressure Jet, Mono-Bloc | Pellet Burner, Pressure Jet, Mono-Bloc | Pellet Burner, Pressure Jet, Mono-Bloc | Pellet Burner, Pressure Jet, Mono-Bloc |

| Fuel Consumption | |||||||

| Pellet Fuel | Kg/hr | 24 | 48 | 72 | 96 | 120 | 144 |

| HSD | Kg/hr | 10.24 | 20.48 | 30.72 | 40.96 | 51.2 | 61.44 |

| PNG | SCM/hr | 12.72 | 25.44 | 38.16 | 50.87 | 63.6 | 76.31 |

| LPG | Kg/hr | 8.9 | 17.8 | 26.7 | 35.6 | 44.5 | 53.4 |

| Connected Electrical Load | |||||||

| PELLET/HSD/PNG/LPG | kW | 2.33 | 3.08 | 4.95 | 5.15 | 6.5 | 8.5 |

| Dimensions & Weight | |||||||

| LxWxH | M | 1.44x0.95x0.96 | 1.98x1.08x1.15 | 2.12x1.08x1.15 | 2.23x1.29x1.48 | 2.7x1.29x1.48 | 2.81x1.42x1.52 |

| Dry Weight | Kg | 650 | 850 | 1050 | 1250 | 1550 | 1850 |

| Chimney Top Diameter | mm | 200 | 200 | 250 | 250 | 250 | 250 |

Pellets vs other fuels comparison chart with saving potential:

| Fuel Type | Kcal/kg | Wood Pellet (kcal/4200) in kg | Saving Potential Range |

|---|---|---|---|

| HSD (Diesel) | 9500 | 2.3 | 30%-50% |

| LPG | 11200 | 2.8 | 20%-40% |

| PNG | 8500 | 2.0 | 30%50% |

| FO | 10000 | 2.4 | 30%40% |

| Parameters | Biomass HAG Values |

|---|---|

| Coil thickness | 2mm |

| Coil Diameter | 45–50mm |

| No. of tubes | 50 to 110 |

| Combustion chamber thickness | 2.5mm |

| Blower Efficiency | 40% more efficiency than diesel blower |

| Cleaning process: Easy | 30 Min |

| Material type | made of high quality, corrosion-resistant stainless steel SS-304 |

| Ash Storage | up to 100–150 kgs |

| Air Pressure | High |

| Running type | Biomass, diesel, LPG, PNG |

| Efficiency | High |

Feature : -

- 1. 20% More Fuel Efficient.

- 2. Easy to Clean in 15 Minutes.

- 3. Can Run on Multiple Fuel.

- 4. Easy to install with Pellet Burner.

- 5. Available with Fully automatic PLC Panel.

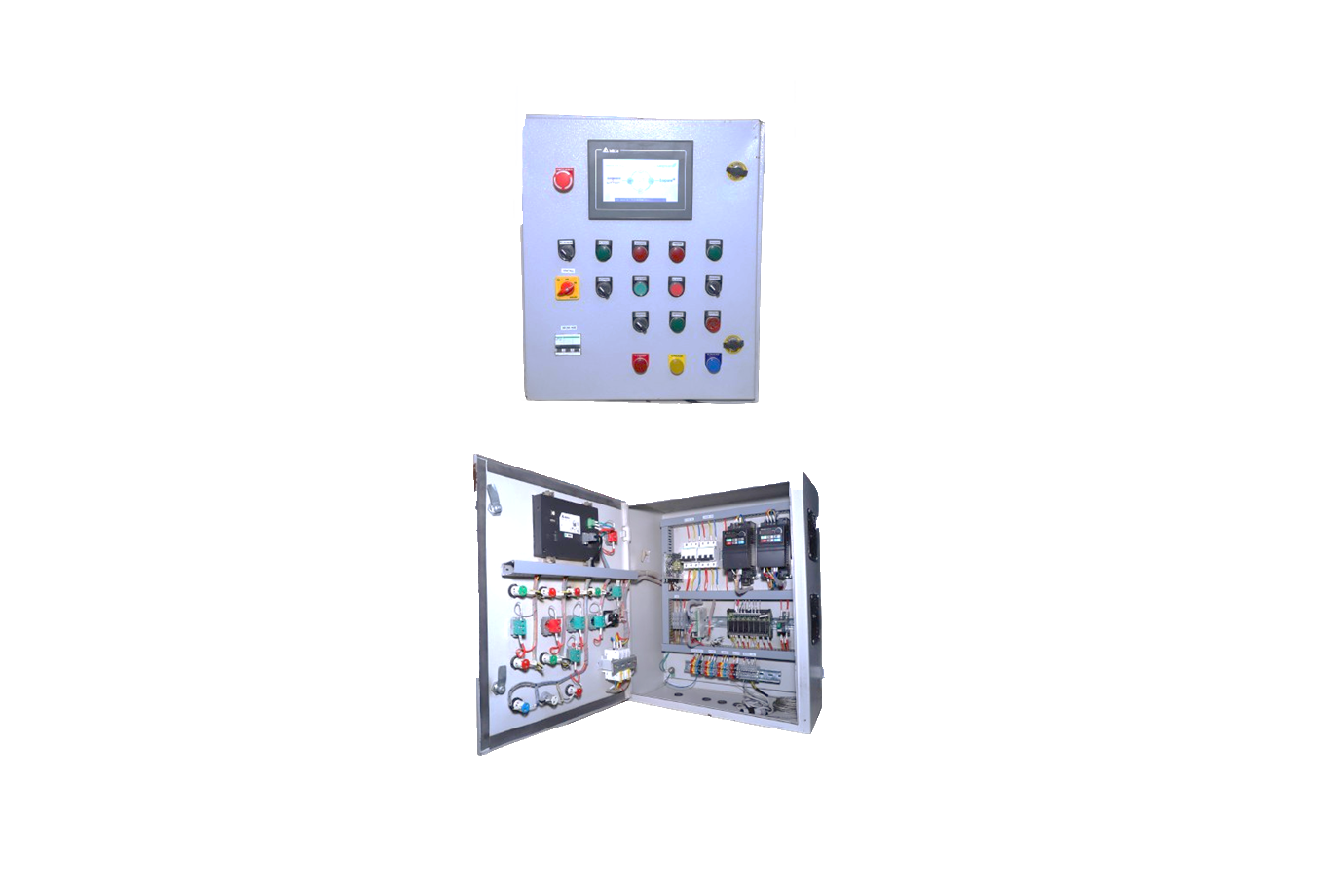

Navshakti PID-Panel

Navshakti PLC-Panel

Feature : -

- 1. Precision Control.

- 2. Steady-State Accuracy.

- 3. Transient Response Improvement.

- 4. Efficient Energy Usage.

- 5. Adaptability to Load Changes.

- 6. Reduced Temperature Fluctuations

- 7.Quick Response to Disturbances.

- 8. Increased System Reliability.

- 9. Ease of Tuning and Optimization.

- 10. Compatibility with Digital Control Systems.

| Navshakti PLC Panel | Local Brand PLC Panel |

|---|---|

| One Touch Start | Manual Start |

| Drive for Blower & Feeder | Single Drive Used for Blower & Feeder |

| 4-Stage Temperature Optimization | 2-Stage Temperature Optimization |

| Delta Based PLC & HMI | Non-Branded PLC & HMI |

| HMI 8" | HMI 4" |

| Automatic Ignition System | N/A |

| More Safety feature for Blower, Feeder Motor & Heater | Less Safety feature |

| Level Sensor For Pellet | N/A |

| Self-Optimizing PID Parameters | N/A |

| Energy Efficiency Optimization | N/A |

| Real-time Feedback and Analytics | N/A |